PV<200: Lower operating costs

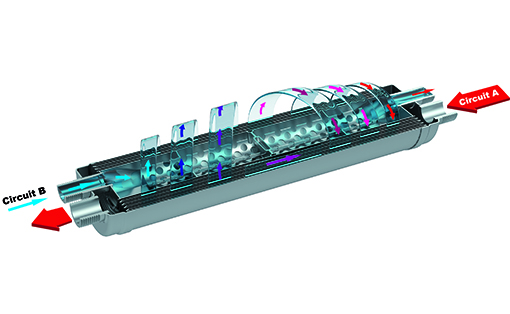

A unique design

Spirec heat exchangers are spirally wound and welded plate heat exchangers without any gaskets (Spirec patent). The internal steam circuit is single-channel, which ensures excellent control of steam distribution. This original exchanger design offers unique advantages: exchange efficiency, very high scaling difficulty, resistance to pressure and water hammer, very low internal volume. Depending on the desired output, several Spirec exchangers can be mounted in parallel on manifolds to cover the requirements.

Main characteristic of STEAM EXCHANGER

The steam exchangers are cylindrical in shape. The spirally wound 316L STAINLESS STEEL plates are fully welded. They are used for the production of domestic hot water, for energy recovery, for the production of heating water. Due to their low internal volume, the PV product is less than 200: they are not subject to PED constraints.

EXTREMELY LONG SERVICE LIFE

Thanks to their unique design, Spirec heat exchangers are particularly robust :

- Resistant to corrosion

- Accepts temperature and pressure variations

- Waterproof and seamless

SPIREC STEAM EXCHANGER

Spirec STEAM EXCHANGER is compact and very efficient. They do not take up much space in a substation. It is easy to assemble them in parallel on manifolds to achieve the required power. Cylindrical in shape, they are resistant to water hammers and temperature variations. Their small volume means that they do not require any regulatory inspection.

Advantages of STEAM EXCHANGER

Serenity

– Spirec exchangers do not scale, so there is no need for maintenance

Environment

– It is not necessary to use decalcifying chemicals, because Spirec exchangers do not build scale

Health security

– Used in the production of DHW, Spirec exchangers limit the risk of legionella development

Quality

– Made of welded 316L STAINLESS STEEL they resist to corrosion due to condensates

They use our solutions